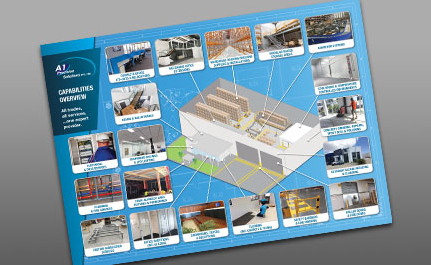

COMMERCIAL OFFICES & BUILDINGS

- Concrete Slab Underpinning, Lifting, and Levelling

- Soil Stabilisation

- Concrete Slab Leak Remediation

- Consultancy, Design, Plans and Permits

- Office and Building Fit-Outs

- Office Extensions and Mezzanines

- Retrofits, Upgrades and Refurbishments

- Business and Office Relocations

- End-of-Lease Make Good and De-Fits

- Building Maintenance Services

- Civil Works

- Utilities and Site Connections

CONTACT US

Concrete Slab Underpinning, Lifting, and Levelling

Industrial and commercial buildings have unique challenges in their design and maintenance. One of these challenges is in their concrete slab. With heavy machinery, wide spans, and uneven loads, overtime a concrete slab may deteriorate, become uneven, or crack. These issues may be caused by use, poor workmanship, or soil settling. Let uncorrected, the damage will only get worse over time.

Commercial properties, both offices and warehouses, may experience concrete slab issues such as:

- An uneven or bouncing slab;

- Cracks and trip hazards;

- Sloping slab;

- Uneven doors and windows;

- Sunken slabs (usually caused by overloading);

- Voids and empty space under the slab due to water, erosion, or poor workmanship;

- And more.

There are a variety of ways to fix these issues, but a fast and cost effective way of doing this is through chemical underpinning. Our chemical unpinning process will ensure any commercial property is brought back to the best possible condition while also making sure it’s life is extended for years to come.

What Is Concrete Slab Underpinning?

Also known a slab jacking or slab lifting, the process of concrete slab underpinning involves lifting a concrete slab so that it is level and stable again. There are a variety of ways to do this, but traditionally excavation is required in order to get under the footing of the building.

While the traditional method is time consuming and disruptive, newer technology, for example resin injection underpinning can do the same job as older methods while also making it less expensive and less disruptive to a business.

Resin Injection Underpinning

Unlike needing to excavate in order to level a concrete slab, resin injection underpinning (sometimes called chemical underpinning), uses a special chemical resin to lift concrete slabs, fill voids underneath the slab, and generally fix sloping and poorly levelled slabs.

The process of resin injection underpinning is relatively simple.

- Once the areas that need to be rectified are found, a 16 mm hole is drilled through the slab and then injected with polyurethane resin;

- Once hardened, the resin expands to lift the slab, fill voids, and more;

- This hardened resin creates a strong base for the concrete slab, preventing future movement.

Overall, the process of resin injection underpinning is fast and often less expensive than other methods. The resin also cures in 15 minutes which means that your business can become operational again quickly.

Resin injection underpinning is an effect slab levelling solution for many circumstances in the commercial, industrial, and even residential space. Feel free to contact us for more information or a consultation on your property’s needs.

CONTACT US FOR MORE INFORMATION ABOUT OUR PRODUCTS AND SERVICES OR TO REQUEST A QUOTATION

COMMERCIAL OFFICES & BUILDINGS

- Concrete Slab Underpinning, Lifting, and Levelling

- Soil Stabilisation

- Concrete Slab Leak Remediation

- Consultancy, Design, Plans and Permits

- Office and Building Fit-Outs

- Office Extensions and Mezzanines

- Retrofits, Upgrades and Refurbishments

- Business and Office Relocations

- End-of-Lease Make Good and De-Fits

- Building Maintenance Services

- Civil Works

- Utilities and Site Connections